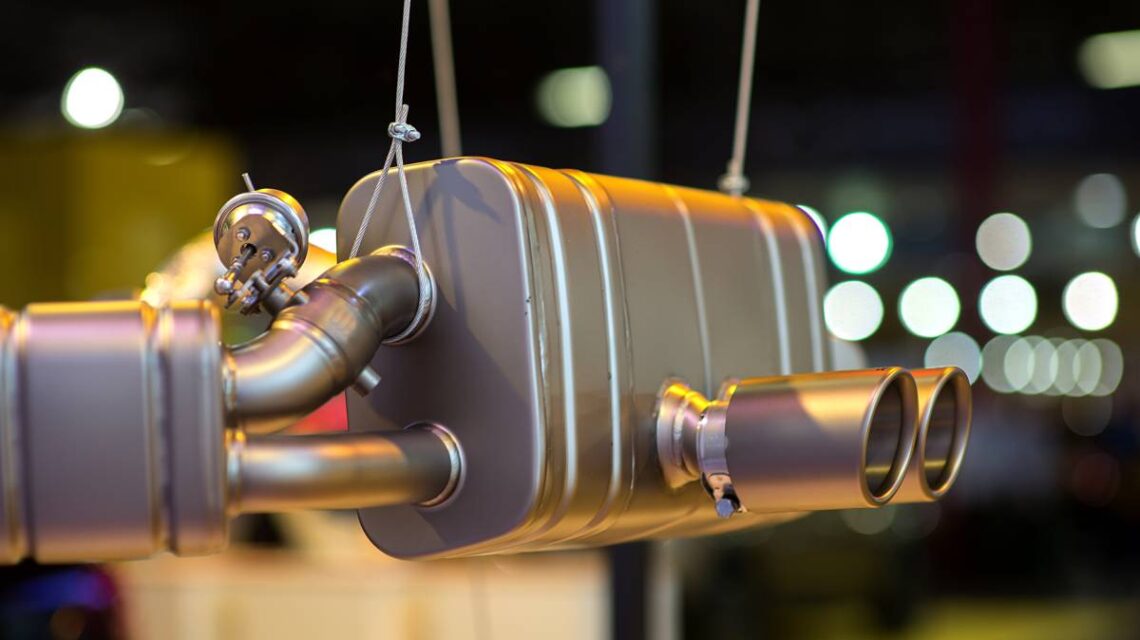

In the construction and mining industries, the performance and reliability of your equipment can significantly impact productivity and operational costs. For excavators, one crucial component that ensures optimal functioning is the exhaust muffler.

Hitachi, a renowned name in heavy machinery, offers high-quality exhaust mufflers designed specifically for excavators, providing numerous benefits that enhance both performance and longevity.

Related article:

The Role of Exhaust Mufflers in Excavators

Exhaust mufflers play a crucial role in the operation of excavators, which are heavy construction machines used for digging and moving large amounts of earth. Understanding the function and importance of exhaust mufflers can help us appreciate their contribution to the efficiency and environmental impact of these machines. Here’s a closer look at what exhaust mufflers do for excavators and why they are essential.

Noise Reduction

One of the primary functions of an exhaust muffler in an excavator is to reduce noise. Excavators are powered by large diesel engines, which can be extremely loud. Without a muffler, the noise produced by the engine would be disruptive and could potentially cause hearing damage to operators and workers nearby.

The muffler works by dampening the sound waves produced by the engine, making the machine’s operation much quieter. This noise reduction is not only crucial for the safety and comfort of the operators but also important for minimizing noise pollution in the surrounding environment, especially in urban areas or near residential zones.

Emission Control

Exhaust mufflers also play a significant role in controlling emissions from excavators. Diesel engines release various pollutants, including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM). Modern mufflers are designed to work in conjunction with other components of the exhaust system, such as catalytic converters and diesel particulate filters, to reduce these harmful emissions.

When excavators use mufflers, they can meet environmental regulations and standards, which is important because construction companies have to work hard to reduce their impact on the environment.

Engine Efficiency

Another important role of the exhaust muffler is to help maintain engine efficiency. The exhaust system, including the muffler, is designed to manage the flow of exhaust gases from the engine. If the exhaust system is not functioning properly, it can lead to backpressure, which can negatively affect the engine’s performance.

Properly functioning mufflers help ensure that exhaust gases are expelled smoothly and efficiently, which can enhance the engine’s power output and fuel efficiency. This, in turn, can lead to cost savings for construction companies due to reduced fuel consumption and less frequent maintenance.

Vibration Reduction

In addition to reducing noise, mufflers also help in dampening vibrations caused by the engine. Excavators, due to their powerful engines and heavy-duty operations, can generate significant vibrations. These vibrations, if not managed, can lead to faster wear and tear of the machine components and can also cause discomfort to the operator. By absorbing and reducing these vibrations, mufflers contribute to the longevity of the excavator’s components and improve the overall working conditions for operators.

Safety and Compliance

Safety is a paramount concern in the construction industry. By reducing noise and controlling emissions, exhaust mufflers contribute to a safer working environment. Lower noise levels reduce the risk of hearing loss and make it easier for operators to communicate with each other, enhancing overall safety on the construction site.

Moreover, compliance with emission standards is not just about environmental responsibility; it’s also about adhering to legal requirements. Failure to comply with these standards can result in fines and other penalties, which can be avoided by using efficient exhaust mufflers.

Why Choose a Hitachi Exhaust Muffler?

Exhaust mufflers are critical components in excavators, helping to enhance performance, reduce noise, and ensure compliance with environmental regulations. Hitachi exhaust mufflers, in particular, offer several advantages that make them a valuable choice for construction machinery. Let’s explore the key benefits of Hitachi exhaust mufflers in more detail.

Superior Noise Reduction

One of the standout features of Hitachi exhaust mufflers is their superior noise-reduction capabilities. Excavators are known for their powerful engines, which can generate significant noise during operation. This noise can be particularly problematic in urban construction sites, where strict noise regulations are in place to minimize disruption to the surrounding community.

Hitachi mufflers are specifically engineered to minimize the noise produced by the engine. They use advanced sound-dampening technologies to reduce the sound levels, making the excavator operate more quietly. This not only helps in complying with noise regulations but also creates a more comfortable working environment for operators and nearby workers.

Enhanced Durability

Durability is another key advantage of Hitachi exhaust mufflers. Construction sites often present harsh working conditions, including exposure to dust, dirt, and varying weather conditions. Mufflers made from subpar materials can quickly succumb to corrosion and wear, leading to frequent replacements and increased maintenance costs.

Hitachi exhaust mufflers are built with high-quality, durable materials designed to withstand these tough conditions. They are resistant to corrosion and wear, ensuring a longer service life compared to standard mufflers. This durability translates to fewer breakdowns and less downtime, which can significantly improve the efficiency of construction projects.

Improved Engine Performance

The performance of an excavator’s engine is closely tied to the efficiency of its exhaust system. Hitachi mufflers are designed to optimize the flow of exhaust gases, which helps improve the overall efficiency of the engine. By ensuring that exhaust gases are expelled smoothly, these mufflers reduce back pressure on the engine. This optimization can lead to better fuel economy, as the engine does not have to work as hard to expel exhaust gases.

Additionally, reducing engine strain can extend the lifespan of the machinery, providing long-term benefits and cost savings. Operators will notice that their excavators run more smoothly and efficiently with Hitachi mufflers installed.

Compliance with Emission Standards

In today’s environmentally conscious world, compliance with emission standards is crucial for construction companies. Diesel engines used in excavators produce various pollutants, including carbon monoxide (CO), hydrocarbons (HC), nitrogen oxides (NOx), and particulate matter (PM). These emissions can have a significant impact on air quality and public health. Hitachi exhaust mufflers are designed to meet the latest emission standards, helping operators stay compliant with both local and international regulations.

These mufflers help reduce harmful emissions, leading to a cleaner environment and helping construction companies avoid fines and legal issues from non-compliance with tightening emission standards.

Installation and Maintenance

Installing an exhaust muffler into your excavator is a crucial maintenance task that can improve the machine’s performance, reduce noise, and ensure compliance with emission standards. Here’s a step-by-step guide to help you through the process:

Preparation

1. Gather Necessary Tools and Equipment:

Before starting, make sure you have all the necessary tools and equipment. This typically includes a wrench set, screwdrivers, pliers, a jack or lift (if needed), and safety gear such as gloves and safety glasses. You will also need the new exhaust muffler and any replacement gaskets or clamps specified by the manufacturer.

2. Safety First:

Ensure the excavator is parked on a flat, stable surface and the engine is completely cool. Disconnect the battery to prevent any accidental starts or electrical hazards while working on the exhaust system.

Removal of the Old Muffler

3. Locate the Exhaust System:

Identify the location of the existing exhaust muffler. It is usually found along the exhaust pipe, connected to the engine’s exhaust manifold and extending towards the rear of the excavator.

4. Remove Protective Shields (if applicable):

Some excavators have protective shields or covers over the exhaust system. If your machine has these, use the appropriate tools to remove them carefully.

5. Loosen the Clamps and Bolts:

Use a wrench to loosen the clamps and bolts that secure the old muffler to the exhaust pipe. These components may be rusted or corroded, so you might need to apply some penetrating oil to make the removal easier.

6. Disconnect the Muffler:

Once the clamps and bolts are loosened, gently wiggle the muffler free from the exhaust pipe. Be careful as it might still hold some weight and residue. Ensure you keep track of any mounting brackets or hardware for reuse.

Installing the New Muffler

7. Inspect and Clean Connection Points:

Before installing the new muffler, inspect the connection points on the exhaust pipe and manifold. Clean any debris, rust, or old gasket material to ensure a good seal.

8. Prepare the New Muffler:

Check the new muffler for any shipping damage. Ensure it matches the specifications of your excavator. Attach any new gaskets or seals as recommended by the manufacturer.

9. Position the New Muffler:

Align the new muffler with the exhaust pipe and mounting brackets. Slide it into place carefully. You might need an extra pair of hands for this step to hold the muffler while you secure it.

10. Secure the Muffler:

Once the new muffler is in position, secure it with the clamps and bolts. Tighten them evenly to ensure a snug fit without over-tightening, which could damage the components.

Final Checks

11. Reattach Protective Shields:

If you removed any protective shields or covers, reattach them securely.

12. Reconnect the Battery:

After ensuring everything is properly installed and secure, reconnect the battery.

13. Test the Installation:

Start the excavator’s engine and let it idle for a few minutes. Listen for any unusual noises and check for exhaust leaks around the connections. Tighten any bolts if necessary.

14. Monitor Performance:

Monitor the excavator during its first few hours of operation with the new muffler. Ensure that it is running smoothly and that the noise levels are reduced as expected.

Do mufflers hurt performance?

Mufflers are designed to reduce noise produced by the engine, but there’s a common concern that they might hurt engine performance. The relationship between mufflers and performance is nuanced and depends on several factors, including the type of vehicle, the specific design of the muffler, and the overall exhaust system configuration.

Understanding the Role of Mufflers

Mufflers work by directing exhaust gases through a series of chambers and perforated tubes that help reduce sound. This process can sometimes create backpressure, which is the resistance to the flow of exhaust gases exiting the engine.

Backpressure and Engine Performance

Backpressure can have both positive and negative effects on engine performance:

- Negative Effects: Excessive backpressure can restrict the flow of exhaust gases, causing the engine to work harder to expel them. This can lead to reduced engine efficiency, lower power output, and decreased fuel economy. For high-performance engines or racing vehicles, where maximum power output is critical, even a small amount of backpressure can negatively impact performance.

- Positive Effects: Some backpressure is necessary for optimal engine performance, particularly in naturally aspirated engines. It helps to improve the scavenging effect, which is the process of removing exhaust gases from the cylinder and drawing in fresh air and fuel. Properly designed mufflers can create just the right amount of backpressure to enhance this effect, leading to better engine performance and efficiency.

Modern Muffler Design

Modern mufflers are designed to balance noise reduction and performance. High-quality mufflers, such as those used in many commercial and industrial applications, are engineered to minimize performance loss while effectively reducing noise and emissions. Here are some ways modern muffler designs achieve this balance:

- Straight-through Designs: These mufflers have a perforated tube that runs straight through the muffler body, allowing exhaust gases to flow more freely while still reducing noise. This design minimizes backpressure and is often used in performance vehicles.

- Chambered Mufflers: These have multiple chambers and baffles to reflect and absorb sound waves. While they can create more backpressure than straight-through designs, well-designed chambered mufflers can still maintain good exhaust flow and performance.

- Advanced Materials and Technologies: Some modern mufflers use advanced materials like stainless steel and incorporate technologies such as active noise cancellation to reduce noise without significantly affecting exhaust flow.

Practical Implications

For most standard vehicles, including excavators and other construction machinery, the impact of mufflers on performance is minimal and well within acceptable limits. Manufacturers design these mufflers to ensure that they do not significantly hinder engine performance while meeting noise and emission standards. In these cases, the benefits of noise reduction and emission control far outweigh any minor performance losses.

Conclusion

So, exhaust mufflers are super important in excavators. They help with reducing noise, controlling emissions, making the engine work better, and reducing vibrations. Hitachi’s top-notch exhaust mufflers are great at reducing noise, lasting a long time, improving engine performance, and meeting emission standards. If operators follow the installation process and understand how it can affect performance, they can make sure their excavators run smoothly.

Getting a good muffler not only makes the machinery last longer but also makes the work environment safer and more comfortable, and helps follow environmental regulations. That’s why carefully choosing and maintaining exhaust mufflers is crucial for getting the most out of your construction equipment.